Electric Linear Cylinders remain in high demand due to applications in window automation, valve operation, and solar panel operation

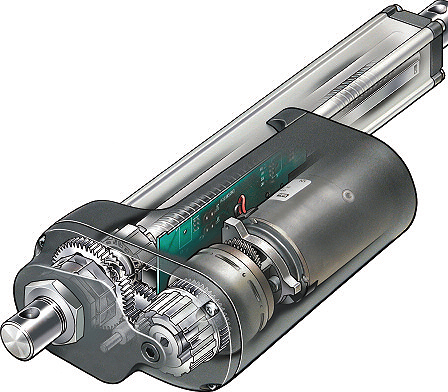

There are different types of electric

linear cylinders including rotary cylinders, screw threads, ball & rod,

ball & cone, piston, and others. They are designed for applications having

high force to weight ratio, high speed, low energy consumption, and for

applications requiring precision and functionality. Application designs are

provided by leading companies and are used in various industries such as

aerospace, power generation, petroleum, chemicals, transportation, metallurgy,

pharmaceuticals, watercraft, and others. Some examples of application areas

include cranes, wind turbines, marine applications, automotive applications,

steam turbines, power generation, lubricants, lubrication oils, and others.

They have an advantage over

traditional piston and gear-based motor systems that makes them highly usable

in high force to weight ratio applications. There are two main categories of

high-efficiency electric

linear cylinders, namely, open-loop control and closed-loop control.

Closed-loop systems use an active control approach for controlling the electric

force produced by the motor. These types of closed-loop systems include

gyro-statically controlled, self-oscillation, rotary vane guided, and linear

electric motors. Open-loop systems involve no control mechanisms; the system is

self-controlled.

This type of system produces low

energy and has high-efficiency characteristics, which make them ideal for

applications requiring torque and high force to weight ratios. The benefits of

using electrical flex tubing are wide-ranging. First of all, flex tubing

provides an economical means for storing electrical flex lines and transmitting

power from them to a destination. This allows the industry to increase its

capacity at a much lower cost than would otherwise be possible. In addition,

the construction of electrical flex tubes requires less material than would

otherwise be required. Finally, the ease with which electrical flex tube

systems can be installed provides a significant cost-cutting benefit to many

industries. Recently, in January 2021, LINAK launched the world’s first

electric linear actuator with IO-Link.

Comments

Post a Comment