What is electroplating? How does the electroplating process work?

Electroplating is the

way toward applying a metal covering on another piece of metal (or another

conductive surface) through an electro-testimony measure. In electroplating,

the saved metal turns out to be essential for the current item with the

plating/covering.

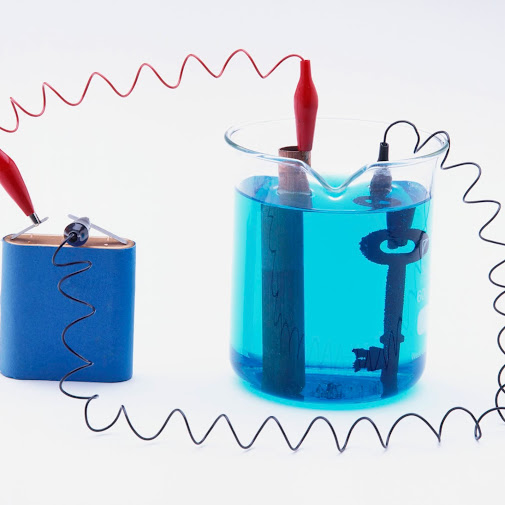

In Electroplating, both an anode and a cathode (the metal part to be

covered) are submerged in an electrolytic shower that is made out of an answer

of salts, including the metal to be plated. An immediate flow (DC) of power is

gone through the arrangement, affecting the exchange of metal particles onto

the cathodic surface, plating the metal onto the thing.

In electroforming, the

mandrel (designed substrate) will be taken out from the item. After the mandrel

is eliminated, the article that remains is made through electro-testimony.

Subsequent to electroforming, it is feasible to perform electroplating to add a

covering to improve erosion obstruction or to get a more appealing (corrective)

item. So as opposed to the two strategies being utilized autonomously, they can

really be utilized in an agreeable way.

A straightforward

illustration of the electroplating cycle is the electroplating of copper

wherein the metal to be plated (copper) is utilized as the anode, and the

electrolyte arrangement contains the particle of the metal to be plated (Cu2+

in this model). Copper goes into arrangement at the anode as it is plated at

the cathode.

Read More : https://bit.ly/3tjwIOG

Comments

Post a Comment